I. Why Choose JC Electromagnetic Iron Remover for Ternary Material Purification?

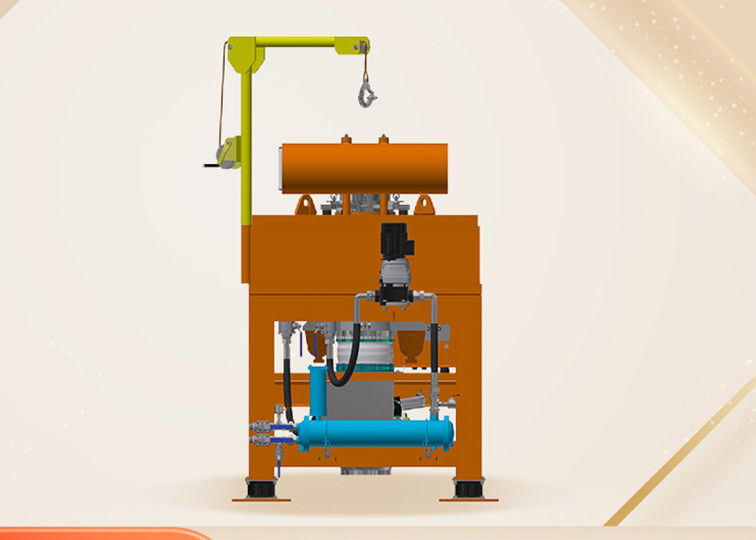

The purity of ternary materials (such as lithium nickel cobalt manganese oxide and lithium nickel cobalt aluminum oxide) used in lithium battery cathodes is directly related to the electrochemical performance and safety of lithium batteries. During the production process, ferromagnetic impurities are easily introduced due to raw material transportation, equipment wear, and other factors. These impurities can reduce the charge-discharge efficiency of batteries, shorten their service life, and even cause short circuits. The JC Electromagnetic Iron Remover can accurately solve this problem. It forms a magnetic field circuit through the electromagnetic coil and carbon steel cabinet, and the magnetic conductive medium in the hollow cavity concentrates the magnetic field, creating a high-field-strength and high-gradient separation environment. This allows it to efficiently adsorb ferromagnetic impurities in ternary materials, providing reliable protection for the purification of ternary materials.

II. Improved Effects After Application

A ternary material production enterprise achieved remarkable results after introducing the JC Electromagnetic Iron Remover. Originally, the unqualified rate of product batches caused by ferromagnetic impurities reached 8%, but after using the equipment, it dropped to less than 1%, significantly improving product quality. At the same time, the automatic operation of the equipment reduces manual intervention, increasing production efficiency by 20% and lowering labor costs. Additionally, the stable operation of the equipment reduces downtime for fault repair, ensuring the continuity of production.

III. Advantages and Features

(1) High Degree of Automation

It adopts an HMI (Human-Machine Interface) and PLC (Programmable Logic Controller) for full automatic control, enabling automatic iron removal, slag discharge, and alarm functions. Frequent manual operations are not required, which reduces the impact of human factors on iron removal efficiency, lowers labor intensity, and improves production safety and stability.

(2) Comprehensive Cooling and Protection Mechanism

Equipped with a transformer oil circulation cooling system, it effectively protects the coil and prevents overheating from affecting the equipment's operation and service life. The constant current design is adopted; when the coil resistance increases, the output voltage is gradually increased to maintain a constant current. This results in minimal changes in power and magnetic field strength, ensuring stable and consistent iron removal effects.

IV. Parameter Table

V. QA

Q1: Will the JC Electromagnetic Iron Remover affect the performance of ternary materials during processing?

A1: No. It only adsorbs ferromagnetic impurities, and the magnetic field does not have any adverse effects on the chemical structure and electrochemical performance of ternary materials. It can maintain the original performance of the materials while ensuring the iron removal effect.

Q2: How to quickly troubleshoot when the equipment malfunctions?

A2: The equipment is equipped with an automatic alarm function, which will sound an alarm when a fault occurs. You can check whether the operating parameters such as magnetic field strength, current, and voltage are abnormal through the HMI interface. You can also check whether functions such as automatic slag discharge and iron removal are normal to quickly locate the fault point for maintenance.

Q3: Is the installation of this equipment complicated on the ternary material production line?

A3: The installation is not complicated. The equipment design takes into account the adaptability to the production line, and professional technicians provide installation guidance. It can be well connected with the existing ternary material production line, with a short installation and commissioning cycle and little impact on production.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!